Introduction

With the continuous advancement of science and technology, glass fiber chopped strands, as an important industrial raw material, are used more and more widely in various fields. This article will delve into the structural characteristics of glass fiber chopped strands and analyze their impact on product performance.

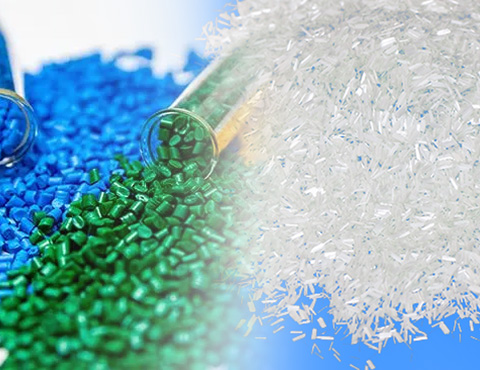

What is chop strand fiberglass?

Chopped fiberglass is a material made from fiberglass strands chopped into short pieces. These short fiber segments are mixed into resin or other reinforcing materials to create a strong and durable composite. Chopped fiberglass usually exists in irregularly shaped segments, with lengths generally ranging from a few millimeters to tens of millimeters. This material offers excellent strength and durability, making it suitable for a variety of industrial and construction applications.

How are fiberglass chopped strands made?

Fiberglass is made through a process of melting glass and drawing it into filaments. After the filaments are cooled, they can be processed in different ways, including chopped glass fiber or woven into cloth.

The preparation process of fiberglass chopped strands involves multiple steps, including:

- Raw material preparation: Choose high-quality fiberglass raw materials, usually molten glass filaments or twisted glass fibers.

- Shredding: Feed fiberglass raw material into specialized cutting equipment, where it is cut into pieces of the required length by rotating blades or cutters. The cutting length usually ranges from a few millimeters to tens of millimeters and is adjusted according to specific product requirements.

- Screening: Chopped glass fiber after cutting may produce fibers of different lengths and diameters. In order to ensure the quality and consistency of the product, the chopped yarn needs to be screened to remove unqualified particles and impurities.

- Coating: In some applications, fiberglass shards may require surface treatment, such as coating with polymers or other reinforcing agents, to enhance their bonding properties with resins or other matrix materials.

- Drying: After processing and screening, chopped glass fiber needs to be dried to remove moisture and improve its stability. The drying process is usually carried out by methods such as oven or air drying.

- Packaging: Finally, the dried fiberglass chopped strands are packed and labeled according to customer needs for storage and transportation.

In general, the preparation process of glass fiber chopped strands involves multiple process links and requires strict control of production parameters and quality standards to ensure the performance and quality of the final product.

How much does fiberglass chopped strand weight?

Chopped strands is a common reinforcement material whose weight depends on several factors, including fiber length, diameter, and density.

First, these short-length fibers are often used in reinforcements, composites and other applications to improve properties such as strength, stiffness and wear resistance. Therefore, the weight of chopped glass fiber is relatively light compared to their long fibers.

Secondly, the weight of strands glass fiber is affected by the length of the fiber. Typically, the longer the fiber length, the greater its weight. short

In addition to length, fiber diameter also affects the weight of a fiberglass cut. Generally speaking, larger diameter fiber cuts are heavier than smaller diameter fiber cuts. This is because fiber cuts with larger diameters contain more glass material and therefore weigh more.

In addition, the density of cut glass fiber is also one of the important factors that determine its weight. Denser fibers are cut more heavily than less dense fibers. Density refers to mass per unit volume, so fiberglass strands with higher density will weigh more.

In practical applications, the weight of fiberglass cut offs is usually described per unit length or per unit volume. For example, let’s say that a cut of fiberglass weighs 100 grams per meter, or 0.1 grams per cubic centimeter. Such a description can help users better understand the weight characteristics of fiberglass shards offs and provide a reference for their applications.

How strong is chop strand fiberglass?

Fiberglass cut-off is a common reinforcing material with excellent strength properties that makes it suitable for a variety of industrial and civil applications.

- First of all, the strength of strands glass fiber is affected by many factors, one of the most important factors is the raw material and production process of glass fiber. High-quality fiberglass is usually made from high-quality glass raw materials and manufactured through advanced production processes, so it has higher strength.

- Secondly, the strength of fiberglass chopped strands also depends on the length and diameter of the fiber. Generally speaking, longer and larger diameter fiber cuts usually have higher strength. This is because long fibers provide more continuous support, and larger diameter fibers contain more glass material and can therefore withstand greater tensile and compressive forces.

- In addition, the strength of chopped strands is also affected by the bonding force between fibers and the arrangement of fibers. Good bonding force can strengthen the connection between fibers, thus improving the overall strength.

Overall, chopped glass fiber offs have excellent strength properties and are suitable for a variety of industrial and civil applications. Its strength is affected by many factors, including raw materials, production technology, fiber length and diameter, bonding force and arrangement, etc. Understanding these factors is critical to selecting the appropriate fiberglass cutoffs and using them correctly in your application.

What is chopped strand fiberglass used for?

Chopped glass fiber is a common reinforcing material with many uses and is widely used in various industrial and civil fields.

- Composites Manufacturing:

Composite materials are materials composed of a variety of materials, usually composed of fiber reinforced materials and matrix materials. They can significantly improve the strength, stiffness and wear resistance of composite materials. Therefore, they are widely used in automobiles, aerospace, shipbuilding and other industries. Composite materials manufacturing.

- Construction industry:

Chopped glass fiber also has important applications in the construction industry. It is often used as insulation, insulation and building structural reinforcement. For example, fiberglass cuts can be used to create insulation for building exterior walls, insulation for roofs, and reinforced concrete in reinforced concrete structures. Its lightweight and excellent strength properties make the building structure more stable and durable.

- Car manufacturer:

In the automobile manufacturing industry, chopped glass fiber is widely used to manufacture body parts, seat structures, interior decoration parts, etc. It can enhance the structural strength and safety of the car while reducing the overall weight of the car and improving fuel efficiency.

- Aerospace:

In the aerospace field, chopped strands is widely used in manufacturing aircraft fuselages, wings, bulkheads, interiors and other components. Its lightweight and high-strength properties allow aircraft to reduce weight and improve flight performance and fuel efficiency.

- Shipbuilding:

In the shipbuilding industry, fiberglass shards is often used to manufacture parts such as hulls, cabins, and decks. It has excellent corrosion resistance and resistance to seawater erosion, which can improve the durability and service life of the hull.

- Other areas:

In addition to the above-mentioned industries, glass fiber chopped strands can also be used in wind power generation, sports equipment manufacturing, electronic equipment, pipes and storage tanks, etc. Its excellent performance makes it have important application value in various industrial and civil fields.

How do you clean fiberglass chopped strands?

Cleaning fiberglass chopped strands offs can be a challenge because they tend to fall apart and stick to surfaces. Here are some common cleaning methods to help you clean fiberglass chopped strands effectivel

- Use a vacuum cleaner:

A vacuum cleaner is an effective tool for cleaning chopped strands. Choose a vacuum cleaner with strong suction power and suitable for floor surfaces and use it with the vacuum head to clean floors and other surfaces. Through suction, the vacuum cleaner can cut off the scattered fiberglass and suck it into the vacuum cleaner to quickly clean the surface.

- Use tape:

Another simple but effective way to clean up is to use duct tape. Apply suitable tape to the contaminated surface and remove quickly. The adhesiveness of the tape can cut off the scattered fiberglass and stick to the tape, allowing for quick cleanup. This method is especially suitable for cleaning small areas of stains.

- Damp mop cleaning:

Using a damp mop to clean floors and other surfaces is also an effective method. Soak the mop in clean water and wring it out, making sure the mop is damp but not dripping. Then, wipe floors and other surfaces with a damp mop to absorb and remove loose chopped glass fiber. When finished, wipe the surface again with a clean, dry mop to remove any remaining moisture.

- Use a damp cloth or sponge:

If there are not a lot of scattered strands glass fiber, you can use a damp cloth or sponge to clean them. Soak a damp cloth or sponge in clean water, wring it out and use it to wipe contaminated surfaces. A damp cloth or sponge can effectively absorb and remove fiberglass strands, leaving the surface clean again.

- To prevent secondary pollution:

After cutting the clean glass fiber, pay attention to prevent secondary pollution. During the cleaning process, fiberglass may be cut off and scattered to other areas, so clean up and dispose of cleaning tools promptly. For example, promptly clean the filter of the vacuum cleaner, replace the tape, clean the mop and sponge, etc. to prevent the fiberglass shards from contaminating other areas again.

- Wear protective equipment:

When cleaning glass fiber chopped strands, be sure to wear appropriate protective gear, including gloves, masks, and goggles. This prevents chopped glass fiber from entering the skin, respiratory tract or eyes, protecting your health.

Overall, cleaning fiberglass chopped strands requires careful attention and the use of proper methods and tools. The cleaning methods introduced above are commonly used and effective, but safety must be paid attention to during the cleaning process to avoid secondary pollution and personal injury.

In Conclusion

In summary, the structural characteristics of fiberglass chopped strands have an important impact on product performance. An in-depth understanding of their structural characteristics can provide important reference for product design and manufacturing. By rationally selecting the type and processing technology of glass fiber chopped strands, we can Effectively improve product performance, meet the needs of different application fields, and promote the development and progress of related fields.

Post time: Mar-06-2024