Free Samples of Permanent Mechanical Fasteners Rivets

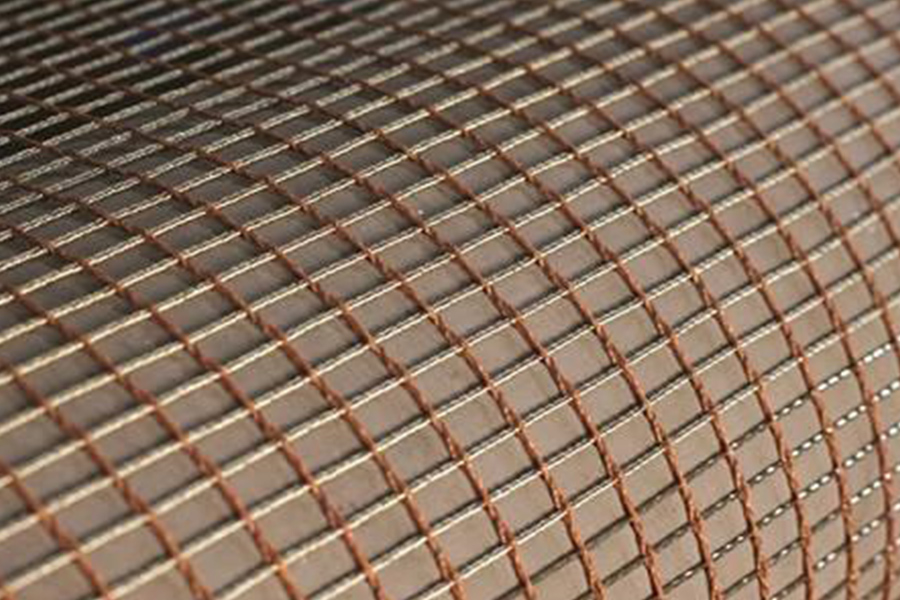

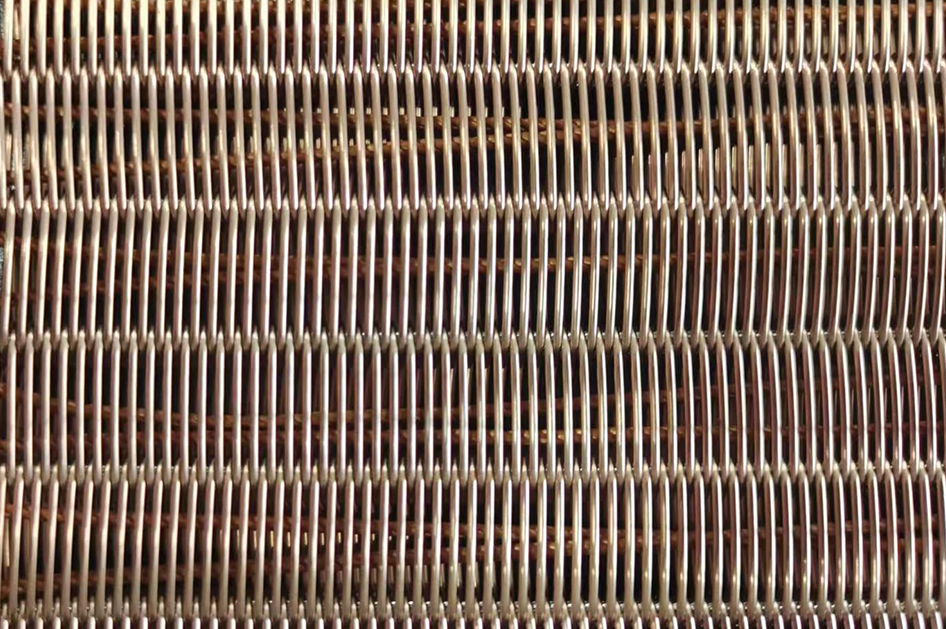

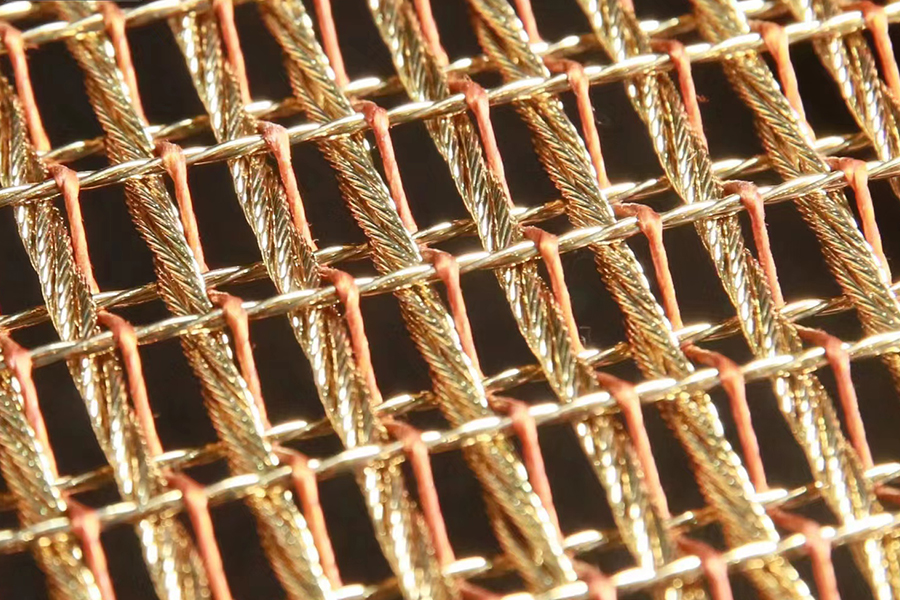

Product Introduction

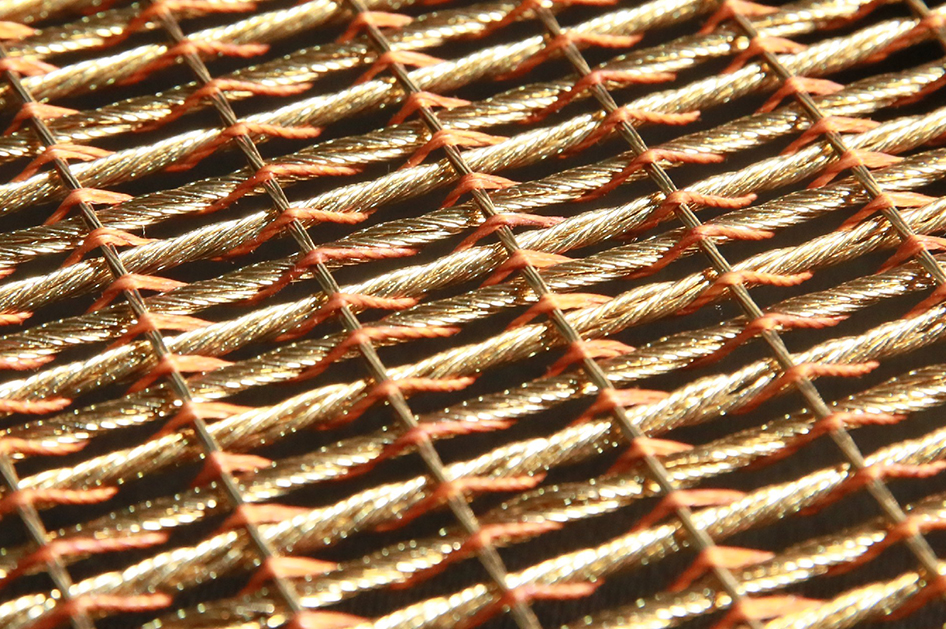

A rivet is a simple, reliable fastener consisting of a solid shaft with a head on one end. Solid rivets are available in aluminum, brass, copper and other materials, and are mainly used in aircraft, solar panels, mobile, electronic products, etc.

We have produced over 50,000 custom precision parts and have an in-depth knowledge and understanding of molds and tooling to meet our customers’ specific needs. Our quality assurance system is state-of-the-art, and we offer fully customized fastening products.

Product Features

Secure and Permanent Fastening:

Rivet tools are commonly used for creating strong and permanent fastenings. They form a tight bond between materials, ensuring a secure connection that is resistant to vibration and movement. This feature is particularly advantageous in applications where a reliable and durable joint is essential.

Ease of Use and Quick Installation:

Rivet tools are generally user-friendly and offer a relatively quick installation process. Once the rivet is inserted into the pre-drilled holes, the tool is used to deform and secure the rivet in place. This efficiency in installation can contribute to increased productivity in manufacturing and construction processes.

No External Power Source Required:

Many rivet tools, especially manual hand tools, do not require an external power source such as electricity or compressed air. This independence from power sources enhances their portability and makes them suitable for use in various settings, including remote locations or areas where power access may be limited.

Cost-Effective Solution:

Rivet tools are often a cost-effective solution for joining materials compared to other fastening methods. They have a relatively low initial cost, and the simplicity of the tools contributes to reduced maintenance expenses. Additionally, the durability of riveted joints can lead to long-term cost savings by minimizing the need for repairs or replacements.

Product Applications

Construction and Building:

Rivet tools are widely used in the construction industry for joining structural components, such as steel beams, aluminum frames, and other building materials. They provide a reliable and secure fastening method for creating sturdy structures.

Metal Fabrication and General Manufacturing:

In metal fabrication and general manufacturing processes, rivet tools are employed to fasten parts in a wide range of products. This includes the production of appliances, furniture, machinery, and other goods where secure connections are essential.

Electronics and Consumer Goods:

In the electronics industry, rivet tools may be used to assemble casings, brackets, and other components in electronic devices. The ability to create compact and secure connections is valuable in the production of consumer goods.

Energy Sector:

In the energy sector, rivet tools play a role in assembling components for power generation equipment, such as turbines and generators. They are also used in the construction and maintenance of infrastructure in the oil and gas industry.

Automotive Manufacturing:

The automotive industry utilizes rivet tools for assembling various vehicle components, including body panels, chassis elements, and interior structures. Riveted joints contribute to the overall integrity and safety of automotive designs.

These diverse applications highlight the versatility and reliability of rivet tools across multiple industries, where strong and permanent fastenings are essential for the integrity and performance of various structures and products.