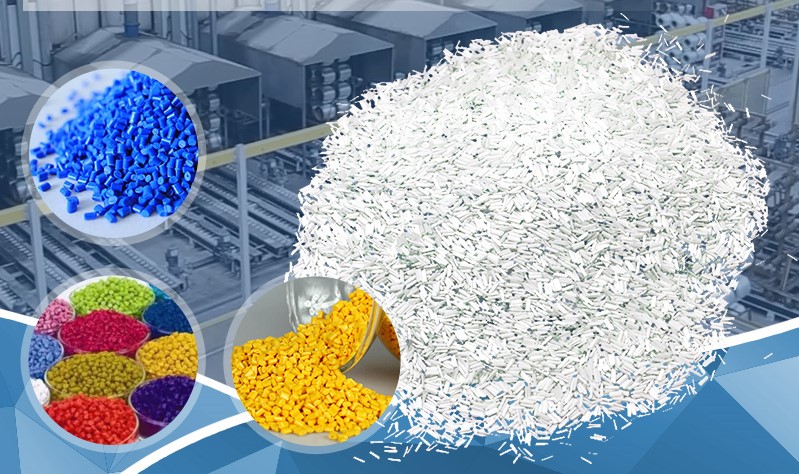

Fiberglass Chopped Strands: A Versatile Material for Color Masterbatch, Plastic Pellets, and More

Fiberglass chopped strands, also known as “short glass fibers“, are a versatile material that can be used in a variety of applications, including the production of color masterbatch, plastic pellets, and other composite materials. With its high strength-to-weight ratio, excellent chemical resistance, and easy processing capabilities, fiberglass chopped strands have become a popular choice for manufacturers in a variety of industries.

One of the main applications of fiberglass chopped strands is in the production of “color masterbatch”. Color masterbatch is a concentrated mixture of pigments or dyes that are used to color plastics, fibers, and other materials. Fiberglass chopped strands can be mixed with the pigments or dyes to create a uniform color throughout the masterbatch. The resulting masterbatch can then be used in a variety of applications, including injection molding, extrusion, and blow molding.

Another popular use of fiberglass chopped strands is in the production of “plastic pellets”. Plastic pellets are small, uniform beads of plastic that are used as raw materials in the production of a wide range of plastic products, such as containers, toys, and automotive parts. Thermoplastic chopped strands can be mixed with the plastic resin to provide reinforcement and enhance the strength and durability of the resulting pellets.

In addition to color masterbatch and plastic pellets, fiberglass chopped strands can also be used to create a variety of other composite materials. For example, they can be combined with other reinforcement materials, such as carbon fiber or Kevlar, to create high-performance composites that are used in aerospace, automotive, and other demanding applications. They can also be used in construction materials, such as drywall, to provide added strength and fire resistance.

One of the main advantages of fiberglass chopped strands is their ease of processing. They can be easily cut, molded, and shaped to fit a wide range of applications. They can also be impregnated with a variety of resins, including polyester, vinyl ester, and epoxy, to create composite materials with different properties and characteristics.

Another advantage of fiberglass chopped strands is their excellent chemical resistance. They are resistant to a wide range of chemicals, including acids, bases, and solvents, making them a good choice for applications where the resulting product will be exposed to harsh environments or corrosive substances.

In conclusion, fiberglass chopped strands are a versatile material that can be used in a variety of applications, including the production of color masterbatch, plastic pellets, and other composite materials. With their high strength-to-weight ratio, easy processing capabilities, and excellent chemical resistance, they have become a popular choice for manufacturers in a wide range of industries. By carefully selecting the appropriate resin and processing techniques, manufacturers can create composite materials with the desired properties and characteristics to meet the needs of their specific applications.

#short glass fibers#fiberglass chopped strands#Thermoplastic chopped strands#high-performance composites

Post time: Mar-30-2023