Better quality, cheaper Nylon Spiral Wrap for wiring protection

Product Introduction

Crafted with precision and engineered for excellence, Spiral Warp plays a pivotal role in optimizing resin flow within composite materials. In vacuum infusion processes, where precision is paramount, Spiral Warp provides a reliable and effective means of guiding resin through intricate pathways. Its unique spiral design facilitates a controlled and uniform distribution of resin, minimizing the risk of voids and ensuring consistent quality across the finished product.

In pre-preg molding, where the precise application of resin is crucial for achieving desired material properties, Spiral Warp shines as an indispensable tool. By strategically directing the flow of resin, this innovative solution enhances the impregnation of fibers with resin, resulting in composite materials with superior strength, durability, and overall performance.

One of the key features that sets Spiral Warp apart is its adaptability to diverse manufacturing needs. Whether you are working on intricate molds or large-scale applications, Spiral Warp can be customized to suit various specifications, ensuring versatility in its application. Its ease of integration into existing processes makes it a seamless addition to any manufacturing setup, allowing for enhanced resin management without disrupting workflow.

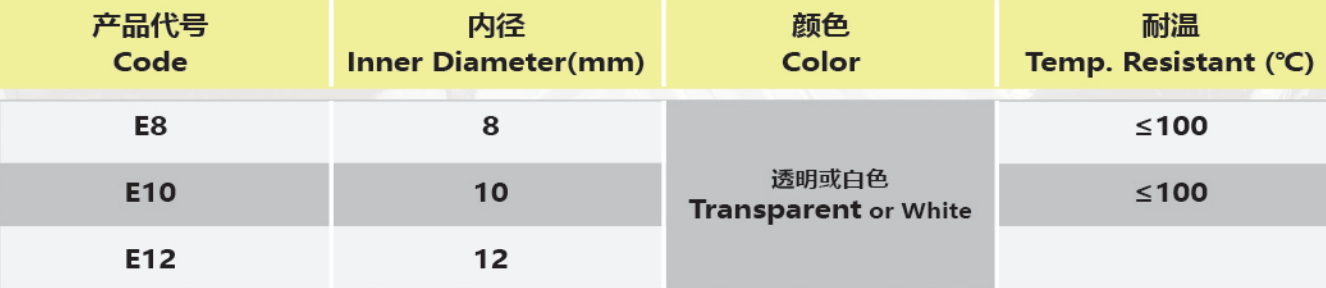

Product Specifications

Product Features

Optimized Resin Flow: Spiral Warp excels in guiding resin through intricate pathways, ensuring a controlled and uniform distribution of resin in vacuum infusion and pre-preg molding processes. This optimization minimizes the risk of voids, enhancing the overall quality of composite materials.

Enhanced Impregnation of Fibers: In pre-preg molding, Spiral Warp plays a crucial role in enhancing the impregnation of fibers with resin. By strategically directing resin flow, it contributes to the creation of composite materials with superior strength, durability, and performance characteristics.

Ease of Integration: Spiral Warp is designed for easy integration into existing manufacturing setups. Its user-friendly design allows manufacturers to incorporate it into their processes without significant disruptions, providing a hassle-free solution for improving resin management.

Durable Construction: Manufactured with high-quality materials, Spiral Warp is built to withstand the demanding conditions of composite manufacturing environments. Its durable construction ensures a long lifespan, offering manufacturers a reliable and cost-effective solution for resin diversion that can withstand the rigors of continuous use.