High-Quality Film Release for Molding: Ensure Effortless Demolding Every Time

Product Introduction

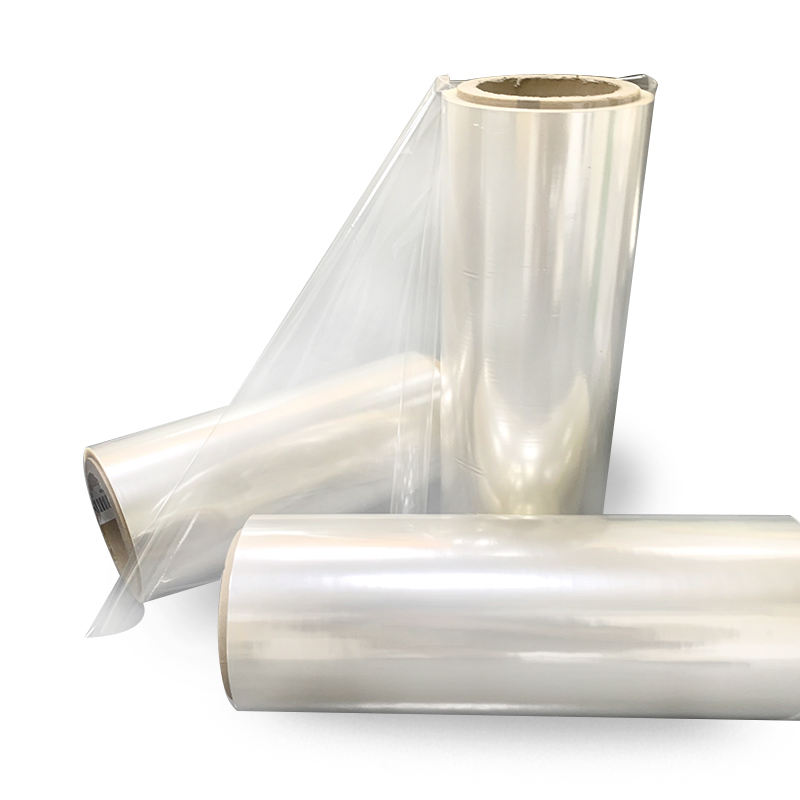

Release Film, a distinguished product under the Raetin brand, is a versatile material designed for a variety of applications. This high-quality film is available in both perforated and non-perforated options, catering to the specific needs of different industries.

The Release Film by Raetin boasts an impressive maximum temperature resistance of 125°C, making it suitable for use in environments where elevated temperatures are a concern. This feature ensures the reliability and stability of the film even in demanding conditions.

With a thickness of 40µm, this release film strikes a balance between durability and flexibility, allowing it to conform to different surfaces while providing ample strength to withstand various mechanical stresses.

Whether perforated for enhanced breathability or non-perforated for added protection, Raetin’s Release Film is a dependable choice for applications where a reliable, temperature-resistant, and thin film is crucial. Its quality construction and adherence to high standards make it a preferred option for industries seeking top-notch performance in their processes.

Product Features

Temperature Resistance: Raetin’s Release Film offers a remarkable advantage with its maximum temperature resistance of 125°C. This makes it suitable for applications where exposure to elevated temperatures is common, ensuring the film maintains its integrity and functionality in challenging environments.

Versatility in Perforation Options: The product comes in both perforated and non-perforated variations, providing versatility to cater to a range of industry-specific needs. The perforated option allows for enhanced breathability and adaptability in certain applications, while the non-perforated version offers added protection and containment.

Optimal Thickness: With a thickness of 40µm, the Release Film strikes a balance between durability and flexibility. This optimal thickness allows the film to conform to different surfaces and substrates, making it versatile for a variety of applications while providing the strength necessary to withstand mechanical stresses.

Reliable Release Properties: As implied by its name, Release Film excels in its release properties. It is designed to effectively release from various materials without leaving residue, making it an ideal choice for processes where a clean release is crucial. This feature contributes to improved efficiency and quality in manufacturing processes.

Quality Construction and Brand Reputation: Raetin, the manufacturer of Release Film, is recognized for maintaining high-quality standards. The Release Film products benefit from this commitment to quality construction, ensuring that users receive a reliable and consistent material. The brand’s positive reputation adds a layer of assurance for industries and businesses relying on these films for their applications.