Factory direct sales 16/20/25/32mm Flow Tube

Product Introduction

A Flow Tube plays a pivotal role as the primary feeding channel for resin in vacuum infusion, L-RTM (Light Resin Transfer Molding), and prepreg processes within advanced composite manufacturing. Serving as the conduit through which liquid resin is efficiently transported to impregnate reinforcing materials such as fibers or fabrics, the Flow Tube is a critical component in ensuring the uniform distribution of resin throughout the composite structure.

In the vacuum infusion process, the Flow Tube operates under the principles of negative pressure, facilitating the controlled flow of resin into the mold. This method is particularly employed in the production of large and intricate composite parts, where ensuring a complete and even impregnation of the reinforcing materials is essential for achieving optimal strength and structural integrity.

In the realm of prepreg processes, where reinforcing materials are pre-impregnated with resin before molding, the Flow Tube is integral for delivering the resin to the designated areas of the mold. This method is renowned for its ability to produce composite components with consistent fiber-resin ratios, resulting in enhanced mechanical properties and performance characteristics.

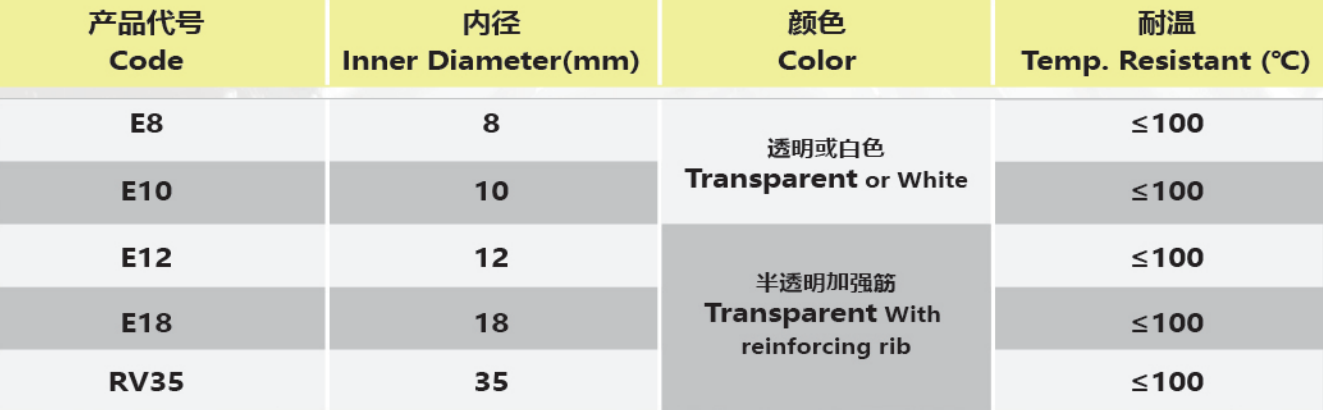

Product Specifications

Product Features

Precise Resin Distribution: One of the key advantages of a Flow Tube is its ability to ensure precise and uniform distribution of resin throughout the composite material. This feature is crucial for achieving consistent mechanical properties and enhancing the overall quality of the manufactured part.

Efficient Resin Infusion: The Flow Tube facilitates efficient resin infusion in processes such as vacuum infusion and L-RTM. By providing a controlled pathway for resin to flow into the mold or onto prepreg materials, it contributes to minimizing voids, ensuring complete wet-out of reinforcing fibers, and enhancing the overall integrity of the composite structure.

Reduced Waste: The design precision and controlled resin flow afforded by the Flow Tube contribute to minimizing resin waste during the manufacturing process. This efficiency not only improves the economic viability of composite production but also aligns with sustainable manufacturing practices by reducing material waste and environmental impact.

Enhanced Process Control: Flow Tubes enable manufacturers to exercise a high level of control over the resin injection process. This control is essential for achieving consistent results in terms of resin impregnation, resin-curing parameters, and final part quality. The Flow Tube, as a critical component of the overall manufacturing system, empowers operators to fine-tune the process for optimal performance and repeatability.