High-precision Rolling Bearing Excellent load-bearing capacity

Product Introduction

Rolling bearings support and guide rotating or oscillating machine elements (such as shafts, axles or wheels) and transfer loads between machine parts. They offer high precision and low friction, thus enabling high rotational speeds while reducing noise, heat, energy consumption and wear.

Product Features

The advantages of rolling bearings are good trade-offs in terms of cost, size, weight, load-carrying capacity, durability, accuracy, friction, etc.

Other bearing designs are often better at one particular property but worse at most others, although fluid bearings can sometimes excel in load-carrying capacity, durability, accuracy, friction, rotational speed and sometimes cost all at the same time. Only plain bearings have as wide a range of applications as rolling bearings.

Common mechanical components used extensively include automotive, industrial, marine and aerospace applications.

Product Applications

There are thousands of different types of roller bearings available to meet specific application requirements.

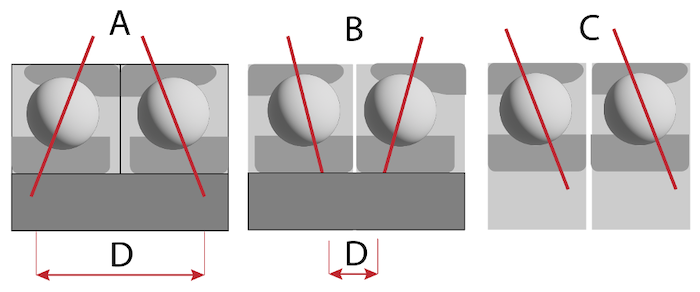

Cylindrical Roller Bearings

These bearings have rollers that are longer than their diameter and can handle higher loads than ball bearings. Our cylindrical roller bearings can handle heavy radial loads and can be used in high-speed applications.

Spherical roller bearing

They can carry heavy loads even while dealing with misalignment and shaft deflection. They can be designed with cylindrical or tapered holes for installation with or without a socket adapter. Spherical roller bearings are available with a variety of internal clearance and cage options to withstand axial loads in either direction as well as heavy shock loads. These bearings are available in bore sizes ranging from 20 mm to 900 mm.

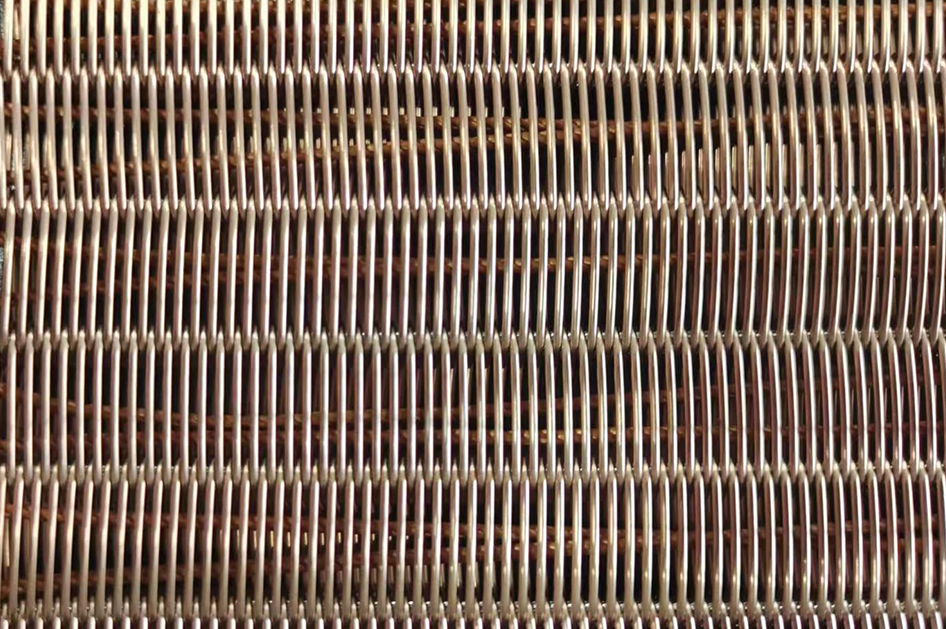

Needle roller bearings

This type of bearing is thinner than traditional roller bearings and can be designed with or without an inner ring. Needle roller bearings are ideal for handling radial space constraints in heavy-load, high-speed applications. The deep-drawn cup style allows for high load capacities and large grease reservoirs while still providing a slim cross-section design. These bearings are available with imperial or metric seals.

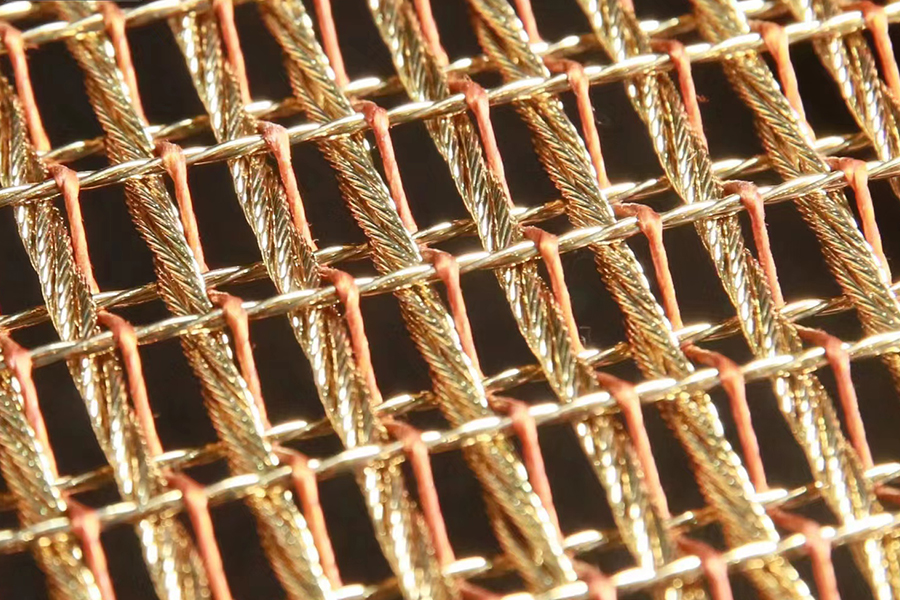

Tapered Roller Bearings

These bearings can support radial and thrust loads. They can only carry axial loads in one direction, so a second transverse counterbearing is required for the balancing struts. Tapered roller bearings are available in imperial and metric sizes.

Roller bearings are used in a wide range of applications, from heavy equipment and machinery to power generation, manufacturing and aerospace.