Connecting tube soft L-Connector push connection quick connector 4-16 mm

Product Introduction

The L-Connector serves as a crucial component in both vacuum infusion and pre-impregnation processes, functioning as a versatile link and guide tube. Its primary role lies in establishing a seamless connection between various elements within these manufacturing processes, facilitating the efficient flow and distribution of materials.

In the realm of vacuum infusion, the L-Connector plays a pivotal role in creating a continuous and controlled pathway for the infusion of resins into composite materials. By serving as a link guide tube, it ensures that the resin is evenly distributed throughout the composite, optimizing the quality and strength of the final product. Its design allows for precision in directing the resin flow, minimizing the risk of air entrapment and ensuring a thorough and uniform impregnation of the reinforcing fibers.

In pre-impregnation processes, the L-Connector acts as a connecting medium, bridging essential components to facilitate the infusion of resins into dry fiber reinforcements. This key element ensures that the resin is effectively delivered to the fibers, saturating them uniformly and creating a well-impregnated material ready for subsequent manufacturing steps. The L-Connector’s design is tailored to enhance the efficiency of resin transfer, contributing to the overall consistency and reliability of the pre-impregnation process.

The L-Connector’s construction is carefully engineered to meet the demanding requirements of these advanced manufacturing techniques. Its material composition is selected to withstand the harsh conditions inherent in both vacuum infusion and pre-impregnation processes, ensuring durability and longevity in service. Additionally, its precise geometry and dimensional accuracy contribute to the reproducibility of these processes, enabling manufacturers to achieve consistent and high-quality composite products.

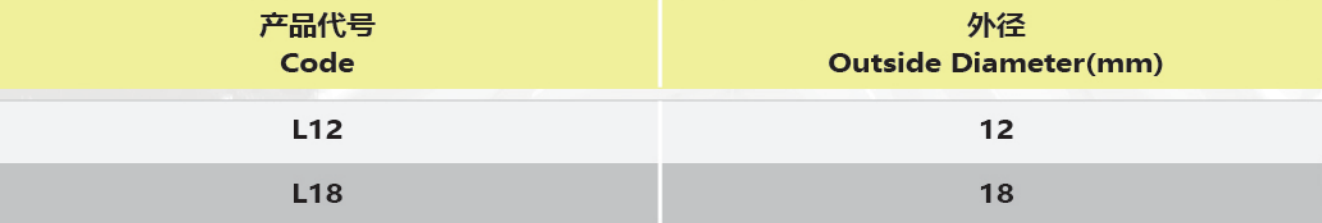

Product Specifications

Product Features

Precision Flow Control: The L-Connector is designed with precision in mind, allowing for accurate and controlled flow of materials in both vacuum infusion and pre-impregnation processes. Its specific geometry and construction enable manufacturers to regulate the distribution of resins with high accuracy, ensuring uniform impregnation and minimizing the risk of defects in the final composite product.

Versatility and Compatibility: One of the key advantages of the L-Connector is its versatility and compatibility with various components and materials used in composite manufacturing. Whether connecting tubes in vacuum infusion setups or facilitating resin transfer in pre-impregnation processes, the L-Connector proves adaptable to different configurations and materials, enhancing its utility across a range of applications.

Durability and Chemical Resistance: The L-Connector is typically constructed from materials chosen for their durability and resistance to the chemicals involved in resin infusion processes. This ensures a robust and long-lasting component that can withstand the demanding conditions of manufacturing. Its resistance to corrosive substances enhances the reliability and longevity of the L-Connector in these critical processes.

Minimized Air Entrapment: In vacuum infusion processes, preventing air entrapment is essential for achieving high-quality composite products. The design of the L-Connector is optimized to minimize the risk of air being trapped during resin infusion. This feature contributes to the production of composite materials with improved mechanical properties and a reduced likelihood of defects.