Valve Polypropylene Standard Saddle Clamp Infusion Valve

Product Introduction

The Infusion Valve stands as a pivotal component within the realm of advanced manufacturing processes, specifically tailored for controlling the precise flow of resin in both vacuum infusion and prepreg applications. In the intricate dance of composite material fabrication, where precision and control are paramount, the Infusion Valve emerges as a technological linchpin, facilitating an optimal resin infusion environment.

In the intricate process of vacuum infusion, the Infusion Valve takes center stage by regulating the rate at which resin permeates the reinforcing fibers. This meticulous control not only ensures an even distribution of resin throughout the composite structure but also plays a crucial role in preventing potential defects such as dry spots or resin-rich areas. The valve’s capability to modulate the resin flow allows manufacturers to achieve a harmonious balance, resulting in composite products with superior strength, durability, and overall quality.

Similarly, in prepreg processes, where resin is already impregnated into the reinforcement material, the Infusion Valve serves as a gatekeeper, managing the resin flow during subsequent stages of fabrication. By precisely adjusting the valve, manufacturers can tailor the resin infusion to meet the specific requirements of each part, whether it be an aerospace component demanding lightweight strength or a high-performance automotive part requiring resilience under extreme conditions.

In summary, the Infusion Valve emerges as an indispensable tool in the toolkit of advanced composite manufacturing. Its role in controlling resin flow during vacuum infusion and prepreg processes is a testament to its significance in achieving precision, consistency, and excellence in the creation of high-performance composite materials. As industries continue to push the boundaries of material science, the Infusion Valve remains a key enabler, empowering manufacturers to craft products that meet the stringent demands of modern applications.

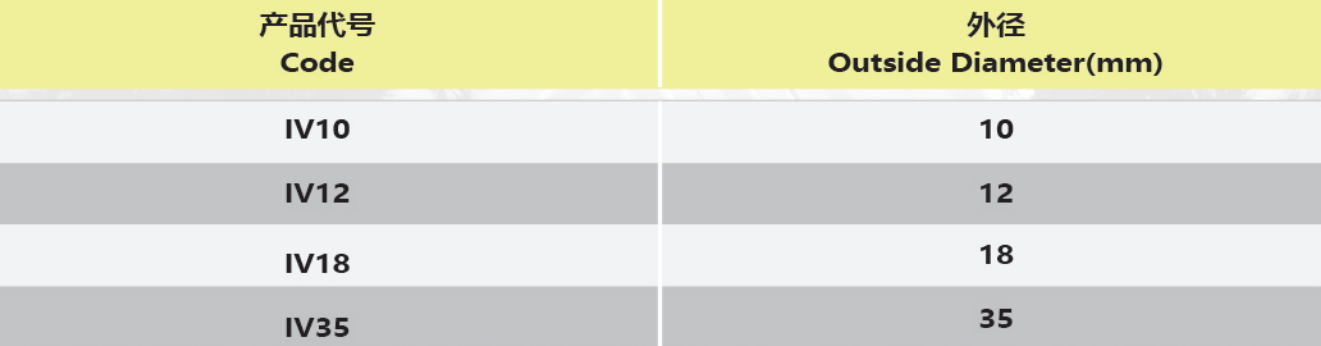

Product Specifications

Product Features

Adaptability to Varying Viscosities:

One of the notable features of the Infusion Valve is its adaptability to a wide range of resin viscosities. This flexibility allows manufacturers to work with different types of resins, adjusting the valve settings to accommodate specific material properties. Whether dealing with low-viscosity or high-viscosity resins, the Infusion Valve provides a versatile solution for diverse manufacturing requirements.

Waste Reduction and Cost Efficiency:

The Infusion Valve plays a crucial role in optimizing resin usage, preventing overconsumption during the manufacturing process. By efficiently controlling the resin flow, it minimizes waste, contributing to both cost savings and environmental sustainability. Manufacturers can achieve a balance between material efficiency and product quality, enhancing the overall economic viability of composite production.

Compatibility with Various Manufacturing Environments:

Designed to meet the demands of different composite manufacturing scenarios, the Infusion Valve boasts a high level of compatibility with various processing environments. Its robust design and adjustable settings make it suitable for integration into different production setups, ensuring that manufacturers can deploy this technology across a spectrum of applications without compromising performance.