Streamlined Connections: T-Connector for Vacuum Infusion and Prepreg Processes

Product Introduction

The T-Connector plays a pivotal role in both vacuum infusion and prepreg processes by serving as a crucial component for tapping into the guide tube. This specialized connector is designed to facilitate a seamless and efficient connection within the intricate framework of these advanced manufacturing techniques.

One of the key advantages of the T-Connector lies in its ability to maintain a secure and airtight connection. This is vital in both vacuum infusion and prepreg processes to prevent any air ingress or resin leakage, which could compromise the integrity of the composite structure. The T-Connector’s robust construction and compatibility with the guide tube make it an essential component for manufacturers seeking to achieve high-quality and defect-free composite products.

In summary, the T-Connector serves as a linchpin in the intricate processes of vacuum infusion and prepreg manufacturing. Its role in tapping into the guide tube ensures a controlled and precise infusion of resin, contributing to the production of superior composite structures. As a reliable and integral component of advanced composite manufacturing systems, the T-Connector plays a critical role in achieving consistent, high-performance results in the aerospace, automotive, and other industries where composite materials are extensively utilized.

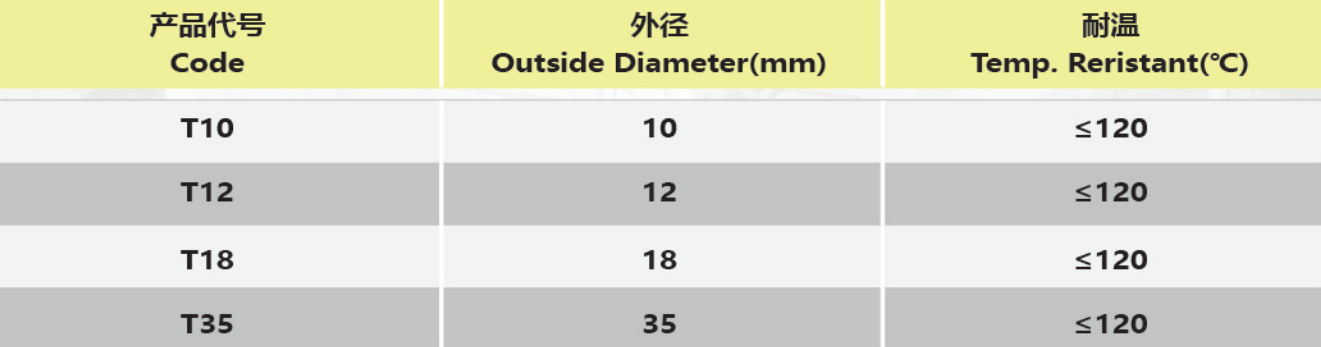

Product Specifications

Product Features

Precision Integration:

The T-Connector excels in providing precision integration within vacuum infusion and prepreg processes. Its design and construction enable a seamless connection to the guide tube, ensuring accurate and controlled resin infusion. This precision is crucial for achieving uniform distribution of resin, thereby enhancing the overall quality and integrity of composite structures.

Airtight Seal:

A key feature of the T-Connector is its ability to establish and maintain an airtight seal. This feature is vital in preventing air ingress or resin leakage during the infusion process. The secure seal ensures that the manufacturing environment remains controlled and that the resin flows precisely as intended, contributing to the production of high-quality, void-free composite components.

Robust Construction:

The T-Connector is engineered with a robust construction that enhances its durability and longevity. This sturdiness is essential for withstanding the demands of composite manufacturing processes, where the connector may be subjected to pressure differentials and exposure to resin and other materials. The robust construction ensures that the T-Connector reliably performs its function over an extended operational lifespan.

Enhanced Process Control:

With the T-Connector in place, manufacturers gain enhanced control over the infusion and prepreg processes. The connector’s design allows for a controlled and regulated flow of resin, contributing to the consistency of material distribution within the mold. This level of process control is critical for achieving desired material properties, minimizing defects, and ultimately producing composite products with superior strength and performance.